We really love coming up with new ideas. It’s not just about making cool stuff for stores, people who like to do things themselves, and experts. Innovation is a big part of who we are and how we do things. We’re so into innovation that we even think about how we package our products. We’re proud to also innovate in packaging design. Our products don’t just look different from others; they also start new trends that everyone follows.

The old way of packaging the soft grip wire brush

In the past, our packaging for soft grip wire brushes was quite different from what it is now. We used a display card that had a slot to hold the brush in place. The card was made to fit snugly, and it had some parts that stuck out to keep it secure. It also had a folded section to make it thicker when it was put in the slot, and there was a hole in it so it could hang on a display rack. But here’s the problem: this packaging didn’t work well. It drew attention to the handle of the brush instead of the most important part, the bristles. And the bristles were completely exposed, which was a bad idea because they are sharp (these brushes are meant for tough jobs like removing rust and paint). People might accidentally grab the bristles, which could lead to injuries. Plus, the exposed bristles were at risk of getting damaged, making the brush wear out faster. Another issue was that the old packaging took up too much space in stores and wasn’t very compact. So, we needed a better solution.

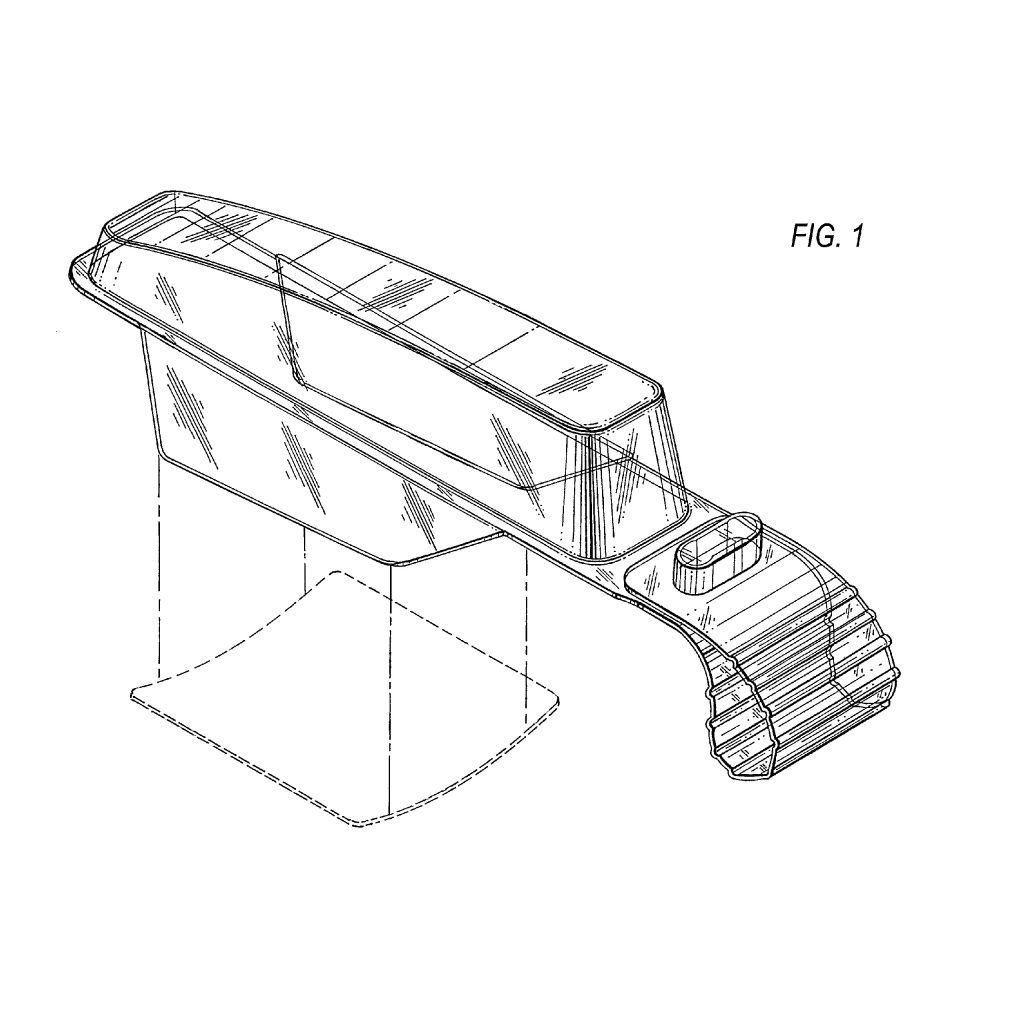

Patent Drawing of Soft Grip Wire Brush

Just like we do with our other products, our research and development team looked at how our competitors were packaging their wire brushes. There are different ways to display brushes in stores. Some put brushes in boxes or sealed containers and stack them up. Others use clear plastic packaging that’s molded to hold the brushes, and some use cardboard with a hole to hang them up for display. When we studied all these methods, we saw that they had some differences that made packaging more expensive. So, we put our heads together and came up with a clever and cost-effective solution. We created a special kind of packaging called a blister. This blister not only keeps people safe from the sharp bristles but also makes sure the wire brush lasts a long time.

Very derivative

Since we made this change, we’ve accomplished a lot. We made better use of the space on store shelves, got rid of the old card-style packaging, and made the brush bristles easier to see. We got the idea from looking at what other companies were doing, and we came up with a totally new way to package our brushes. The result? People liked it a lot and thought it was really clever. So, if you see packaging that looks like what we’ve described, remember that ALLWAY® was the first to do it.